Many industrial engineers struggle to secure long-lasting, efficient insulation that stands up to moisture, fire, and mechanical stress. Finding a versatile, all-in-one thermal insulation solution is a real challenge in demanding industries.

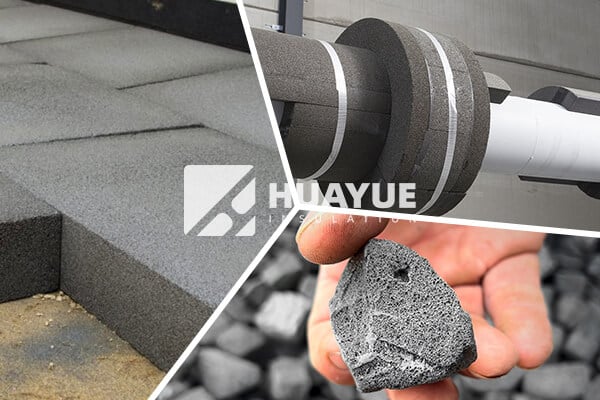

Cellular glass insulation is a rigid, lightweight material used for thermal insulation in industrial tanks, pipes, cryogenic systems, and building envelopes because it does not absorb water, resists fire, is chemically stable, and won’t degrade over time.

If you manage critical plant infrastructure like I do, you want insulation materials that do more than just slow down heat loss. You need something that will not break down in harsh conditions, resists corrosion under insulation, and handles changing regulations without constant upgrades. Cellular glass stands out for engineers who won’t settle for short-term fixes. Let’s take a closer look at its specific uses and how it compares to other solutions.

What is cellular glass insulation used for?

Every day, I see project teams ask whether cellular glass is just another option or a must-have in specialty environments. The confusion can make it easy to overlook its real value.

Cellular glass is widely used to insulate tanks, pipelines, and cryogenic systems where fire resistance, water resistance, and durability matter most. Typical applications include chemical storage tanks, LNG processing equipment, and sensitive cold storage.

When I recommend cellular glass to a facility’s engineering team, I highlight that a single insulation layer can help keep chemicals stable at very low or very high temperatures. The cellular structure blocks water vapor entirely, stopping the slow, hidden failure modes you get from water infiltration, microbial growth, or freeze-thaw cycles. Unlike some traditional insulation types, cellular glass remains robust, even if exposed to spills, aggressive chemicals, or sudden temperature swings. I have seen cellular glass maintain its structural integrity where fiber or foam systems degrade, which saves us from having to schedule emergency repairs or costly full system replacements.

If you need to insulate pipelines that transport fluids below freezing or tanks that must meet strict fire safety codes, cellular glass provides a consistent, dependable barrier. In my own work, specifying foam glass in high-risk process environments has helped us improve long-term reliability and keep maintenance predictable—something auditors and plant managers both appreciate.

Is cellular glass the same as foam glass?

It can be hard to tell the difference between insulation products, especially when suppliers use different names for what seems like the same material. People often ask if cellular glass and foam glass are interchangeable.

Yes, cellular glass is the same as foam glass. The terms refer to lightweight insulation made by fusing glass powder with a foaming agent, which creates a rigid, closed-cell structure filled with tiny, sealed air pockets.

In projects where I am choosing materials, I encounter both terms in specifications and datasheets. Whether it’s labeled cellular glass or foam glass, the product performs the same way. The structure is made by heating recycled glass with a foaming agent, forming a solid with trapped bubbles throughout. This structure makes it water-resistant, fire-resistant, and gives it remarkable strength compared to many fibrous or flexible insulation types.

So, no matter what you call it, you are getting a single, inorganic material that offers reliable insulation without organic binders or hidden structural weaknesses. I always stress to my colleagues that this is more than just a branding choice—it makes procurement less confusing and assures you that you are getting the tested performance you expect.

What is the difference between fiberglass and cellular glass insulation?

People often assume that all glass-based insulation works the same way. However, there are key differences between fiberglass and cellular glass that impact performance and lifespan.

Cellular glass is a rigid, closed-cell insulation made of pure glass, while fiberglass consists of fine glass fibers and is typically softer and more flexible. Cellular glass is fully water- and vapor-proof; fiberglass absorbs moisture and can degrade over time.

When I have compared the two for industrial projects, I focus on their ability to resist tough site conditions. Cellular glass does not absorb water, even if the outer jacket is damaged or exposed. That means it naturally prevents corrosion under insulation (CUI) and keeps constant thermal performance regardless of leaks. Fiberglass is good at reducing heat flow initially but loses effectiveness as fibers settle or absorb humidity. In chemical plants or facilities with changing process conditions, the difference shows up in maintenance records: fiberglass often needs replacement after water events, while cellular glass stands firm.

There is also a key difference in load-bearing capability. Cellular glass panels can support heavy protective layers or walkways without crushing, essential for tank roofs or pipe racks. I have replaced crushed fiberglass years after installation, but never needed to do so for cellular glass. If you are looking for long-term, stable insulation—especially where moisture is a risk—cellular glass is usually the safer choice.

Is cellular glass insulation fireproof?

Safety is a top priority for any plant manager or engineer, and fire resistance in insulation materials is often non-negotiable. Clients ask if cellular glass can deliver on this promise.

Cellular glass insulation is non-combustible and fireproof. It will not burn, emit smoke, or release toxic gases, even in direct flame or extreme heat.

The fire performance of cellular glass has stood out in my projects, especially where regulations require proven, tested fire ratings. Because the base is pure glass, there are no organic binders or fillers to catch fire. Instead, it maintains its shape and protective qualities during and after a fire event. This gives emergency teams the time they need and keeps the rest of the plant safer for longer.

I remember a case where fire broke out near an insulated storage tank. The cellular glass layer protected the tank walls long enough for responders to act, with almost zero damage to the insulation afterward. Its properties go beyond “not easily burning”—it simply does not participate in a fire. That kind of peace of mind is often worth the upfront investment, especially in high-value, high-hazard sites.

What is the temperature range for cellular glass insulation?

For cryogenic tanks and high-temperature process lines, you need insulation that delivers a stable performance across a huge temperature range. The limits of any material will affect your whole operation.

Cellular glass insulation operates reliably from -268°C up to +482°C (-450°F to +900°F), covering everything from extreme cold storage and LNG processing to hot process tanks and piping.

From my experience, this range means you can use cellular glass on the same site for cold nitrogen lines and hot exhaust ducts, without needing different materials or extra design effort. It doesn’t melt, outgas, or sag under heat, nor does it crack or lose insulation power in deep cryogenic service. In practical terms, I have used it to simplify material lists during site upgrades and to avoid unpleasant surprises when process conditions shift unexpectedly.

Cellular glass does not just survive extreme temperatures—it keeps the same insulation value and structural shape, ensuring reliable energy savings, no matter what temperature profile your process demands.

Conclusion

Cellular glass insulation stands out for its durability, fire resistance, water-tightness, and extreme temperature range, making it the go-to choice for critical industrial applications.