In industrial insulation, mistakes can mean heavy costs, equipment failure, or safety risks. Choosing the right material is critical.

Foam glass insulation is a lightweight, rigid, and non-absorbent material made from high-quality glass. It offers exceptional thermal insulation, fire resistance, and long-term durability for demanding applications.

Selecting insulation materials for industrial tanks is hard. There are choices, compromises, and hidden dangers. I have seen poor decisions lead to unexpected corrosion, high maintenance costs, or even system shutdowns. Foam glass insulation offers a simple, robust option for many harsh environments. If you care about preventing corrosion, reducing energy losses, and avoiding water problems, foam glass is worth a closer look.

What is foam glass insulation used for?

Insulation technology often gets overlooked, but the right material can change outcomes, budgets, and even lives.

Foam glass insulation is used to insulate pipes, tanks, and vessels in petrochemical, chemical, food processing, and cryogenic industries. Its moisture resistance, fireproof qualities, and strength make it reliable for harsh conditions.

I have visited sites where tanks stand exposed to wild temperature swings and humidity. Without the right insulation, the losses stack up. There can be condensation, energy waste, and expensive fire hazards. Foam glass insulation steps in to solve these problems. Its closed-cell structure means it will not absorb water. This reduces the risk of corrosion under insulation (CUI)—a silent killer for steel tanks and pipelines.

Engineers like Hans Müller often choose foam glass for jobs where other materials fail. Cryogenic tanks need stable, moisture-proof protection to prevent cold losses and maintain safety. Chemical process tanks benefit from foam glass’s resistance to chemical attack and corrosion. Chilled water pipes stay dry, saving energy and stopping condensation. In fire protection zones, foam glass acts as a barrier because it will not burn. Whenever someone asks me what insulation to pick for the most aggressive, demanding jobs, foam glass is always my first answer.

How is foam glass made?

The production of insulation sounds simple from the outside, but inside, every detail affects performance and quality.

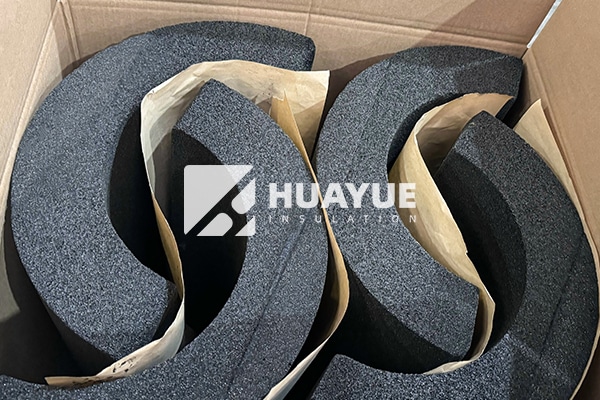

Foam glass is made by finely grinding high-quality glass, mixing it with a foaming agent, then heating the blend until it expands into a closed-cell structure. This process results in lightweight, rigid blocks with uniform bubbles and no large pores.

I have seen plants where raw materials change everything. We at HUAYUE use only pure, self-manufactured glass—not recycled, low-quality material. Some suppliers cut costs by mixing in poor-grade recycled glass. This leads to uneven bubbles, big pores, and even weak bonds held together with glue. You would be surprised how often this goes unnoticed until insulation fails on the job, sometimes years later.

The production steps are simple to follow. First, we melt clean glass raw materials in-house for controlled purity. Then the glass is ground into a fine powder. Next, a foaming agent like carbon is blended in. After that, special kilns heat the mixture, and at about 800-900°C, the agent generates gas which foams the melt. The glass expands into rigid, closed-cell blocks. Finally, blocks are cut for precise edges and all broken pieces are sorted out. Unlike many manufacturers, we never ship re-glued or defective pieces. This method delivers strong, long-lasting foam glass that maintains performance.

Many manufacturers do not sort out defective blocks or repair them with glue. We never ship such material. This commitment delivers reliable, high-compressive strength foam glass that lasts.

Is foam glass insulation waterproof?

Water is the enemy of insulation, often leading to hidden damage and expensive repairs.

Foam glass insulation is completely waterproof due to its closed-cell structure. It will not absorb moisture and keeps its insulating and protective properties even under long-term exposure to water.

Foam glass is different from fibrous materials like mineral wool. Its fully closed-cell design means each bubble in the block is sealed off, making it impossible for water to pass through or be absorbed. Some insulation types, when wet, lose all strength or become a breeding ground for corrosion. I have seen tanks insulated with porous materials soak up water and degrade fast. Trapped water leads to corrosion, ice formation, and even mold.

Foam glass avoids these problems. If, for example, I choose insulation for a tank exposed to rain or process water, I know foam glass will not let liquid inside. It keeps the steel safe and maintains its structure while other materials sag or fail. When moisture and waterproofing matter most, foam glass puts my mind at ease.

What happens if foam glass insulation gets wet?

Many insulation disasters are caused by water—once inside, the material is done for. But does that apply to foam glass?

If foam glass insulation gets wet, it simply sheds the water. It will not soak up moisture, lose thermal resistance, or weaken structurally—which makes it ideal for tough, wet environments.

I remember a site in northern Europe where a tank’s insulation was accidentally drenched for hours during a maintenance event. Other blocks failed fast—fiber insulation slumped and foam panels curled. The foam glass was undamaged. We inspected it, wiped away the water, and it stayed as strong as ever.

When foam glass gets wet, there is no absorption and no loss of insulation. It dries quickly, returns to work, and keeps protecting the steel structure beneath. Looking at mineral wool or polyurethane foams, these often have to be replaced after water contact because they degrade or lose their shape. Foam glass’s total resistance to water means longer tank life and less maintenance. That gives peace of mind for years, no matter what the environment throws at your facility.

Conclusion

Foam glass insulation provides reliable, waterproof, and fireproof protection for industrial tanks and equipment, delivering peace of mind and lower long-term costs.