When you think about insulation for critical projects, choosing the right material can be stressful and confusing.

Cellular glass insulation is a lightweight, inorganic thermal insulation material made by expanding glass with a foaming agent. Its closed-cell structure gives it excellent insulation properties, fire resistance, and water resistance.

If you need insulation that stands up in tough environments, it’s important to look closely at its composition. Cellular glass offers unique advantages because of how it is made and what it can do. I always pay special attention to the details that make the difference in practical performance and long-term reliability. Let’s explore cellular glass more deeply.

What is cellular glass insulation used for?

Insulating industrial tanks, cryogenic systems, chemical plants, pipelines, and roofing systems all need reliable, durable insulation materials.

Cellular glass insulation is used to protect equipment and structures against heat loss, condensation, fire hazards, and water damage. It is valued for its ability to keep systems stable and safe.

I have seen cellular glass insulation used on chemical storage tanks where performance and safety matter most. It is chosen because it completely blocks water, does not react with chemicals, and resists fire. When a plant engineer like Hans Müller wants to fight corrosion under insulation and get maximum energy savings, cellular glass insulation is often the answer. Its closed-cell structure prevents moisture from moving in, which is critical in humid, aggressive environments.

Many of the projects I help with use cellular glass for both hot pipes and chilled water lines. It stays solid even at very low or very high temperatures, so it fits wherever steady, reliable insulation is required. I notice a lot of engineers look for cellular glass where long-term durability is important. This is because it does not age, crumble, or absorb liquids over time. In some places, it also serves as fire protection on rooftops, adding safety to the structure itself.

Are foam glass and cellular glass the same?

These two terms are used often, and it’s easy to think they mean different things.

Foam glass and cellular glass are actually the same material. Foam glass is another name for cellular glass insulation, both produced by foaming glass to create a block with millions of closed bubbles.

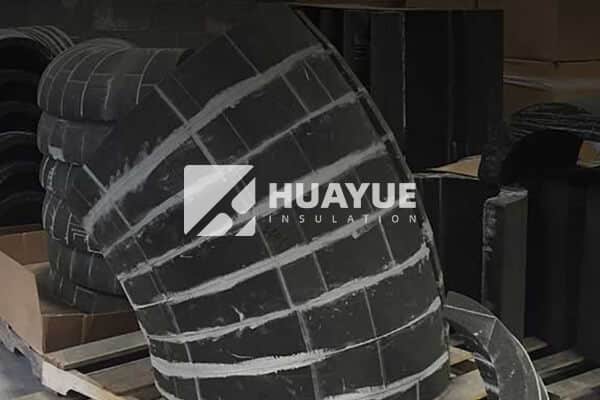

Every time I speak with colleagues who use the term “foam glass,” they mean the same blocky, lightweight insulation that others call “cellular glass.” Both refer to the product created by mixing glass with a foaming agent, heating it until it expands, and then cooling it into rigid boards or shapes. The closed-cell structure is key. These tiny bubbles are what give the material its strength, water resistance, and insulating power.

It’s important to note that there is no practical difference between the two terms when specifying products for industrial or building use, especially when looking at standards and technical datasheets. When sourcing foam glass, what matters most is the quality and purity of the original glass and how evenly the bubbles are distributed in the final product. At HUAYUE, the process starts with 100% high-quality, self-produced glass, and it results in a perfectly uniform structure. This guarantees that every block of insulation does the job as promised—reliable, safe, and long-lasting.

Is cellular glass insulation hot or cold?

You want insulation products that work for both hot and cold projects. Some materials only suit one application, but cellular glass is different.

Cellular glass insulation is effective for both hot and cold systems. It works well for high-temperature pipelines and cryogenic tanks, maintaining insulation regardless of heat or cold.

Temperature extremes challenge most insulation products. I have helped select cellular glass for piping systems that run at very high temperatures. It keeps heat inside tanks or pipes without degrading, even after years of use. It’s equally effective for extreme cold. In cryogenic applications, such as LNG storage or cold water systems, cellular glass prevents condensation and energy loss.

What makes cellular glass stand out is its resistance to temperature cycles. It never shrinks, warps, or cracks when temperatures change suddenly. It does not absorb water at any temperature, so frost damage is not a concern. I see this as a major advantage for facilities where both hot and cold systems are close together.

Plant engineers need to know their insulation will not become a weak link in demanding environments. Cellular glass answers that need. It stands firm, whether holding heat in an industrial process or keeping cold inside a cryogenic tank, with no risk of breakdown due to temperature swings.

Benefits of Cellular Glass Insulation

Finding the ideal insulation brings peace of mind, but what exactly sets cellular glass apart from the rest?

Cellular glass insulation offers long-term durability, water resistance, fire protection, non-absorption, and high load-bearing strength—ideal for demanding industrial applications.

For me, the benefits start in the manufacturing process. Since our foam glass is made from pure, self-manufactured glass, there are no impurities or weak spots inside. The surface is free of large holes and the edges stay precise and straight after cutting. This matters to engineers because gaps or flaws can let moisture or heat slip through, causing problems later.

I never trust materials that have been glued together from broken pieces. Gluing patchwork foam glass means hidden cracks, reduced strength, and unpredictable fire safety. At HUAYUE, any damaged parts are removed before shipping. This makes sure only the best insulation reaches the plant. A uniform, unbroken structure means stronger insulation and higher fire performance.

Cellular glass insulation is fully waterproof. It never absorbs any liquid. This blocks corrosion under insulation, which is a real danger in chemical plants. It is also noncombustible. Even at high temperatures, cellular glass does not catch fire, making it safe for roofs and tank linings. Its compressive strength is impressive, handling heavy loads without deforming. Over time, it does not shrink, crumble, or lose effectiveness. This stability supports engineers who need to control costs and minimize maintenance.

Choosing cellular glass insulation is a commitment to safer, longer-lasting, and more energy-efficient industrial projects.

Conclusion

Cellular glass insulation is a trusted solution for long-term protection, reliable performance, and maximum safety in demanding industrial environments.