Sometimes, we look for a building material that checks all the boxes—tough, water-tight, fireproof, and long-lasting—but it sounds too good to be true.

Foam glass insulation is used to protect, insulate, and waterproof a wide range of building and industrial projects—from subslabs and roofs to tanks and piping, even under extreme temperature swings.

You rarely find a solution that works below ground, in a wet basement, or on a chemical tank roof, yet foam glass fits each of those roles. Once I saw it in action, I realized how much ground it covers. If you work with tank systems or build below-grade, or you’re after a mold-free, maintenance-friendly insulation, keep reading—foam glass could change how you tackle your next project.

What is foam glass insulation used for?

When you need a material that can block heat, resist water, and take a beating without breaking down, foam glass almost always comes up.

Foam glass insulation finds use beneath concrete slabs, foundation walls, flat and green roofs, parking decks, and inside walls. It is key in cryogenic tanks, pipelines, rooftop gardens, and any spot needing fireproof, non-absorbent, heavy-duty insulation.

Let’s break down where foam glass shines. In buildings, I’ve seen it laid under concrete—it acts as a thermal break and stops groundwater from leaking in. Architects use it on rooftops, both flat and green, because it handles weight and never soaks up rainwater. Parking decks and airport runways take tons of weight—foam glass shrugs it off, working as a load-bearing insulator. In walls, both steel and timber, it doubles as a thermal and fire barrier.

Move into industry, and you’ll find it on tanks, pipes, and cryogenic vessels—places where temperatures go from Arctic cold to furnace hot. Engineers love it because it just doesn’t break down or let in moisture. The marine sector, HVAC systems, and any operation where you want no leaks—these are all natural fits for foam glass.

When I recommend foam glass for underground and below-grade slabs or foundations, I know I’m giving my clients a solution that blocks moisture and gives energy savings from day one. When it’s used on roofs or runways, the compressive strength stands out. In industrial plants, on piping or tanks, I’ve seen foam glass work for decades without failures that you get with other common insulations.

Can FOAM GLASS insulation get wet?

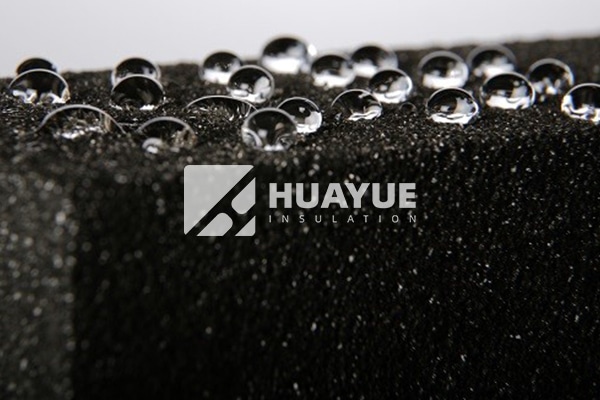

We all know how destructive water can be—mold, rot, rust, and icy damage inside insulation are real headaches.

Foam glass insulation cannot absorb water or vapor at all because its structure is fully closed-cell. Even in flooded or high-humidity conditions, it will not take up moisture or lose performance.

This is the number one reason why, when I get calls about pool rooms, laundry basements, or bottling plants, I always bring up foam glass. Regular insulation—like fibrous or plastic foams—can suck up water and become heavy, moldy, or totally lose their strength. I’ve pulled apart failed insulation from pools or roof gardens and seen the mess leftover. Foam glass doesn’t act like a sponge. Its completely closed bubbles lock out even vapor, so it stays dry and solid, no matter the environment.

This makes it useful for underground construction, critical roof layers, and, of course, inside piping or tanks with hot or cold liquids flowing through. Engineers in the food and pharmaceutical industry also count on this property to prevent bacteria from finding a home inside their insulation.

In short, other insulations like fiberglass, mineral wool, or foams can absorb water and break down. Foam glass stays dry, never growing mold or rotting, and keeps full strength and performance even in the wettest environments.

What is the life expectancy of FOAM GLASS?

We often ask, how long will an insulation truly last before we have to tear it out?

Foam glass insulation regularly lasts 50 years or longer in building, piping, or tank applications, due to its chemical stability, non-absorption, and fireproof nature.

Most insulation starts with good performance but breaks down after repeated freeze-thaw, chemical exposure, rodent attacks, or simple aging. Not foam glass. It’s literally made from glass—melted and foamed to trap air inside. It won’t rot, rust, or support bugs. I once returned to a chemical tank insulated with foam glass 25 years earlier—it looked, and tested, nearly new. No dust, no shrinkage, no evidence of mold or chemical decay.

In industrial facilities, this kind of predictable durability is gold. No plant manager wants to face hidden corrosion or insulation failure inside a critical pipe run or below a cooled tank. Safety regulators, too, value this: foam glass is totally fireproof and won’t contribute to blazes or release toxic gases under heat.

Even under asphalt covers in parking decks or bridges where chemicals, oil, or salt are present, foam glass outlasts everything else. When I spec foam glass, I say: you’re not just buying insulation, you’re buying peace of mind for decades.

Conclusion

Foam glass insulation delivers reliable thermal protection wherever you need moisture-proof, fire-resistant, heavy-duty, and long-lasting performance—from roofs and runways to pipes and tanks.”