If you select the wrong thickness for your insulation, you may face problems like heat loss, condensation, or wasted money.

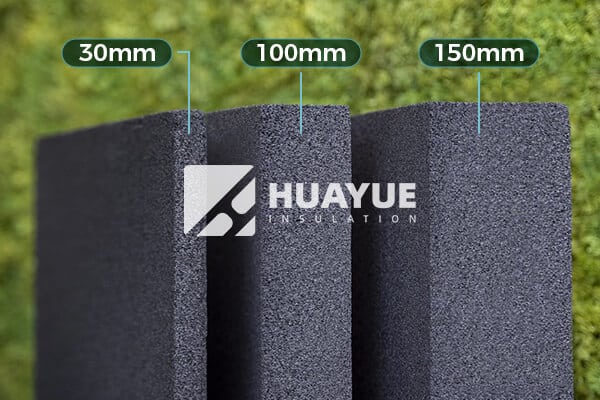

The right thickness of cellular glass insulation depends on your desired temperature control, energy savings, and local building codes. Usually, for industrial tanks and pipelines, thickness ranges from 30mm to 150mm (3-15cm), based on your needs.

Sometimes you think thicker always means better, but that is not true for every project. You may need good insulation for cryogenic tanks, but not every wall or pipe needs the thickest available. Later, I will walk you through the critical questions about cellular glass R-value, its drawbacks, and what makes it unique. Read on to make sure you get the right product for your tanks or pipelines—and avoid expensive mistakes.

What is the R-value of cellular glass?

Insulation that can’t block heat is useless. Many don’t know how cellular glass compares to other materials. I’ve had buyers ask, is the R-value high enough for tough environments?

Cellular glass insulation usually offers an R-value of approximately 3.3 to 4.0 per inch (25mm), making it a strong choice for both thermal efficiency and long-lasting performance.

When thinking about R-value, you want a number high enough to block heat but not so high that it becomes hard to handle or install. R-value is how we measure how much heat gets stopped by your insulation. The typical R-value for cellular glass is not the highest among all insulation types, but it is very reliable for conditions where water or fire are concerns.

Here is what I see: cellular glass works well in places where you need good insulation and zero water absorption: chemical tanks, cold storage, or anywhere water and fire are big risks. If you build with too thin an insulation, you lose heat and money. If you go too thick, you may pay more than you need or run into fitting problems. I usually recommend between 3cm and 15cm, which we can customize to your exact project.

What are the disadvantages of cellular glass insulation?

Nobody talks about what can go wrong until something breaks. I have seen even experienced engineers get tripped up by the downsides of cellular glass.

The main disadvantages of cellular glass insulation are its higher cost, brittleness, and the need for careful handling during installation compared to more flexible materials.

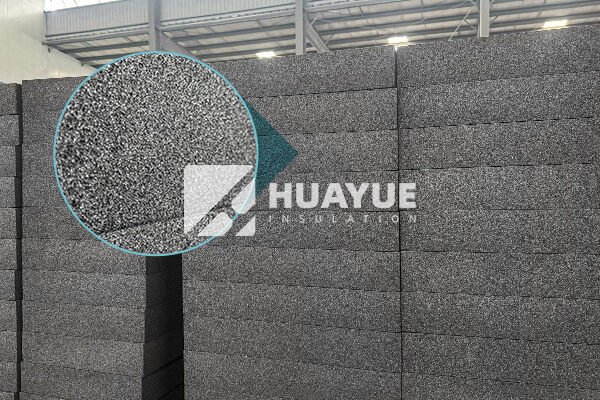

From my project experience, the best advantages of cellular glass are its zero water absorption and strong resistance to fire and chemicals. But there are limits. The material can be brittle. If dropped or struck, it can crack or break. That means you must plan your shipping and installation carefully. I always tell my clients to use proper packing and tools.

Also, cellular glass insulation can cost more than mineral wool or foam plastic. This might worry your budget, especially on large projects. Sometimes, its stiffness can be a problem around tight curves or oddly-shaped parts. Finally, if you need very high R-values with thin insulation, cellular glass may not be your first pick. But for tanks, especially cryogenic or chemical, the long-term benefit of no corrosion or water damage wins over initial material costs.

Is FOAM GLASs the same as cellular glass?

Some buyers get confused by names. I often hear the question: if I order FOAMGLAS, am I just getting cellular glass, or is there a difference?

FOAMGLAS is a brand of cellular glass insulation. All FOAMGLAS is cellular glass, but not all cellular glass is FOAMGLAS; there are other manufacturers and product choices.

It’s easy to mix up a brand with a material. FOAMGLAS is a famous brand made by Owens Corning, but any insulation with a glass-cell structure and closed-cells is called cellular glass. This is how I help clients avoid confusion: when you need a certain thickness (for example, 3-15cm), you just have to specify cellular glass, but let the brand depend on project needs, cost, or supply.

In my business, we provide cellular glass insulation made in China, not just FOAMGLAS. Our products come in custom thicknesses to suit different tanks and pipelines. Buyers can compare test reports, certifications, and prices to find what fits best. It helps to keep your requirements clear—if you need high compressive strength, or superior resistance to chemicals, ask for the real performance data, not just the brand name. Firm up your specs and your project will have no problems, no matter what name is on the box.

Conclusion

Cellular glass insulation thickness, R-value, and brand choice depend on your needs. Know the facts and pick the right product for your tank system to stay safe and efficient.