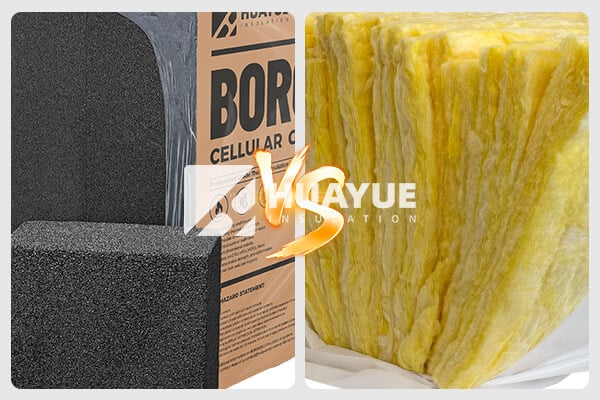

Choosing the right insulation for tanks means battling heat loss, moisture, and corrosion. Which material truly stands up to the test?

Foam glass offers higher resistance to water absorption, fire, and chemical exposure than fiberglass. This means longer service life and lower risk of corrosion under insulation, making it the top choice for demanding industrial applications.

When I face the challenge of insulating chemical or cryogenic tanks, I need a solution that will keep the system reliable for decades. Selecting insulation is about safety, cost, and long-term performance. Hans Müller, chief plant engineer in Germany, faces these questions every time he upgrades a tank. Working with him, I see firsthand how the smallest details impact tank life, maintenance costs, and compliance. Now, let’s break down the options further.

How do foam glass and fiberglass insulation differ in water resistance?

Water infiltration can ruin insulation and put tanks at risk. This leads to hidden damage and costly repairs.

Foam glass does not absorb water at all, while fiberglass can soak up moisture. This makes foam glass ideal for preventing corrosion and protecting tank integrity.

I’ve watched water damage destroy insulation that looked perfect on installation day. Fiberglass feels light and easy to handle, but it has a weakness—its fibers can trap water. Over time, I have found wet fiberglass loses its insulation power. Even worse, trapped moisture promotes corrosion under insulation (CUI), one of the main threats to both steel and alloy tanks.

Foam glass, on the other hand, is made by fusing recycled glass with foaming agents. It creates a structure with closed cells, each one airtight and watertight. When I install foam glass, I know water will not get in. This prevents rust and other problems hidden beneath the surface.

In places with heavy rain, humidity, or exposure to chemicals, foam glass stays dry and strong. For Hans Müller, fighting CUI is a daily battle, so he prefers foam glass whenever possible. I agree. For tanks that store chemicals or cryogenic liquids, water resistance is a must-have feature.

Which insulation material provides better fire and chemical resistance?

Industrial tanks need protection from fire and harsh chemicals. Many insulation options cannot survive in these conditions.

Foam glass is completely fireproof and resists most chemicals, which means it keeps tanks safe even in dangerous environments.

I always worry about how insulation reacts to fire or exposure to aggressive substances. Fiberglass does not burn easily, but high temperatures can still damage it, and many industrial chemicals break down its fibers over time. I’ve had customers replace fiberglass insulation more often than they expected because of chemical attack or fire safety concerns.

Foam glass solves these problems with its naturally non-combustible makeup. It doesn’t release toxic gases when exposed to flame. There’s simply no fuel to burn. In chemical plants like Hans’s in Ludwigshafen, tanks often stand alongside acids, alkalis, and solvents.

Foam glass resists almost every chemical I encounter, so it lasts even when spills or leaks happen. In case of fire, foam glass forms a barrier, keeping the inner tank cooler for longer and giving responders more time to react. This extra level of safety is important to me and to anyone responsible for tank health in hazardous locations.

Which insulation material is strongest under heavy loads or harsh conditions?

Industrial tanks often support heavy weights and face vibration, pressure, and sudden shocks. Insulation must be tough enough to handle these demands.

Foam glass carries heavy loads without losing shape or strength. Fiberglass can compress and weaken if stressed.

Tank surfaces can buckle under heavy pipes or access platforms. I’ve seen fiberglass insulation flatten and lose its insulating value when weight is applied.

Maintenance crews sometimes damage the insulation while working around tanks, causing expensive heat loss and unsafe zones. Fiberglass is soft by nature. It bounces back a little, but repeated stress destroys its structure.

Foam glass is different. Its rigid, dense design lets it carry loads without compressing. I use it under pipes, ladders, and other attachments on tank surfaces. The material does not sag or break down over time.

It works well in cold climates and in places where thermal cycling happens often. This stability matters to Hans, who needs his tanks to operate nonstop, year-round, without insulation failure.

Whenever someone asks me about upgrades, I recommend foam glass for the most demanding spots, where reliability matters most.

Conclusion

Foam glass outperforms fiberglass in water resistance, fire and chemical safety, and load-bearing capacity, ensuring safer, longer-lasting insulation for industrial tanks.