Global demand for energy-saving building materials is on the rise. It is vital to choose the right insulation for projects and budgets now.

Foam glass prices vary widely based on specifications, quantity, and supplier location. For most bulk needs, pricing ranges from $5 to $20 per square meter, with customized sizes or higher-density panels costing more.

Foam glass pricing can seem complex. Many factors affect cost, from material density and thickness to shipping distance and customization options. I have spent nearly three decades working with foam glass projects across green roofs, industrial tanks, and power plants, so I know how prices fluctuate by market and application. Customers often ask about the true cost of foam glass for their projects. I always recommend looking beyond the headline number and considering the product’s lifecycle benefits, such as reduced maintenance and energy savings. These benefits often outweigh minor differences in upfront costs. Let’s break down what impacts foam glass prices and why bulk buyers see the biggest advantages.

Is Foam Glass Waterproof?

In critical applications where water resistance matters, choosing a material that holds up is essential. Moisture can quickly damage other types of insulation.

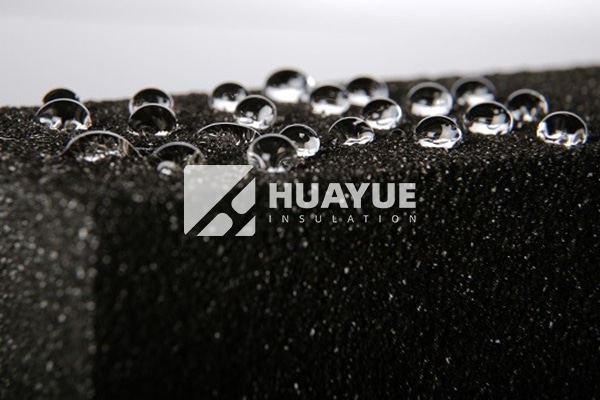

Foam glass is 100% waterproof. Its closed-cell structure prevents any water absorption, even in wet or submerged environments.

Water resistance is one of the core strengths of foam glass insulation. I have seen this proven in chemical plants, cryogenic tanks, and roof projects where even a small leak can cause expensive damage or risk corrosion under insulation (CUI). Foam glass’s non-absorption comes from its manufacturing process, which traps millions of hermetically sealed glass cells. This structure blocks all liquid and vapor passage, keeping tanks and piping safe from moisture. In Germany, for example, Hans Müller manages plant tanks that cannot tolerate insulation breakdown. He always asks for foam glass because he knows water won’t get inside, even after years of exposure. Many other insulation products claim water resistance but can absorb water slowly, leading to performance loss over time. Foam glass stands out by delivering a zero-absorption guarantee for every environment.

Buy Foamglas Insulation (Cellular Glass) | Bulk Deal Prices?

Market dynamics change every year. Project managers need reliable suppliers who can deliver high volumes of foam glass at fair prices.

Bulk buyers access lower foam glass prices. Discounts increase with order size, and direct factory negotiations lock in the best rates for large projects.

Bulk negotiations play a huge role in the real cost of foam glass. At HUAYUE, we see bulk buyers enjoy price reductions of 10-30% compared to retail purchases. I encourage every client, from plant engineers like Hans to big developers, to work directly with manufacturers for substantial projects. Bulk deals mean better customization, reliable supply, and stronger after-sales support. Location also matters. Factories based near major ports in China—like ours—reduce logistics costs for European and North American buyers. Our experience shows that long-term contracts, annual volume deals, and planning large purchases ahead of time drive the best value for industrial and construction partners. If you’re considering a bulk foam glass buy, reach out to suppliers who can show you proven results, flexible customization, and transparent quotes. The payoff in long-term project performance is well worth it, especially when maintenance and energy savings are factored in.

What is Foam Glass Used For?

Many customers want to know which applications make the most sense for foam glass. The answer goes beyond walls and rooftops.

Foam glass is used for thermal insulation in cryogenic tanks, chemical plants, green roofs, and power stations. It is chosen for fire safety, waterproofing, and structural stability.

When I started supplying foam glass nearly thirty years ago, most orders were for industrial tanks and pipelines that needed top-notch durability. Today, usage has expanded. Cryogenic storage tanks use foam glass insulation because it does not absorb water, resists fires, and has high load-bearing strength. Chemical factories like those managed by Hans depend on their CUI protection. Green roofs are another major area. Foam glass supports plant growth by keeping substrates dry and warm, all while resisting root intrusion. Power stations use foam glass in hot and cold pipe insulation due to its reliability over decades. Wherever customers need insulation that will not degrade under moisture, pressure, or temperature changes, foam glass is a trusted choice.

Foam Glass: Key Factors Influencing Price

Project success depends on understanding cost drivers for foam glass. Clients need transparency before committing to large investments.

Density, panel thickness, custom sizes, shipping distance, and certification all impact foam glass pricing. Higher standards and custom fabrication raise costs, while bulk orders reduce unit price.

After hundreds of foam glass projects, I’ve learned what factors really move the needle on pricing. Density is key—higher-density panels offer better mechanical strength and durability, but they cost more to produce. Thickness affects insulation value, so thicker panels provide better efficiency but use more material. Custom sizing—shaped blocks or specialized panels—requires more time and increases labor costs. Logistics matter, especially for overseas buyers, since shipping heavy insulation can add up. Quality certifications, like CE or SGS (which we offer), ensure consistent performance but also add testing and documentation expenses. Bulk orders always bring the unit price down. I advise clients to balance performance needs with budget realities. Investing more up front in certified, high-density foam glass pays off in reduced operating costs and longer service life.

Conclusion

Foam glass prices depend on several factors, but selecting high-quality insulation leads to lower risks, a longer service life, and stronger project results.