Industrial tank insulation failures can lead to expensive downtime, safety risks, and damage to valuable equipment. Foam glass pipe insulation is designed to solve these problems.

Foam glass pipe insulation provides outstanding thermal protection, unmatched resistance to moisture, and reliable long-term durability for industrial tanks and piping. It stands out for its non-absorbent property and fire resistance.

If you are maintaining large chemical plant tanks, you want a solution that keeps heat loss low, stops corrosion under insulation, and reduces maintenance costs. Foam glass is trusted by world-class industrial engineers because of its unique combination of performance features. In my experience, it is hard to match the efficiency and safety foam glass brings to the table. Here’s how it sets the standard.

What is the R-value of foam glass pipe insulation?

Everyone in the insulation industry knows R-value matters for thermal efficiency, but some materials lose effectiveness over time or in wet conditions.

Foam glass pipe insulation has an R-value of roughly 3.3 to 4.0 per inch, and it does not lose this value due to moisture or aging. This consistent performance makes it ideal for critical industrial environments.

When I select insulation for a new tank, I check not just the R-value on paper, but how that value holds up in real-world conditions. Foam glass insulation has a closed-cell structure, meaning it does not absorb water, so its R-value remains stable even in harsh, wet environments where other insulations fail. The high R-value means less energy is lost, which keeps tanks and pipes at target temperatures much more consistently. Over time, the result is lower energy bills, fewer equipment failures, and a safer facility. I have seen insulation systems lose their effectiveness after a few seasons but foam glass retains its R-value over its whole service life.

Does foam glass pipe insulation really work?

In some plants, insulation material breaks down, absorbs water or corrodes the tank beneath, causing both safety hazards and costly repairs.

Foam glass insulation truly works for industrial tanks and piping, providing solid protection against heat loss, fire, and corrosion for decades without absorbing water or shrinking.

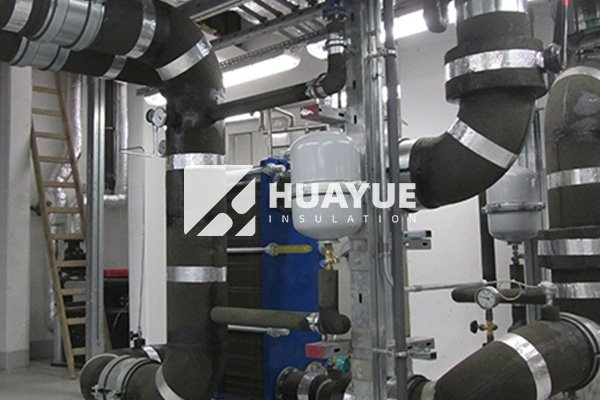

Long-term performance is what sets foam glass apart from other options. I have installed many kinds of insulation over the years, but most struggle with moisture and mechanical stress. Foam glass, because of its unique composition, is immune to water absorption. It offers continuous thermal insulation without breaking down. Fire resistance is another advantage. In one of our chemical plants, traditional insulation melted when exposed to extreme conditions; foam glass stayed in place and did not burn or produce toxic smoke. This material also prevents corrosion under insulation – a major problem for metal tanks. FOAM GLASS does not hold moisture, so it does not create an environment for corrosion to begin. Its closed-cell glass structure does not change over time, so maintenance teams spend less time checking or replacing insulation.

What is foam glass pipe insulation?

Many ask what foam glass actually is, and how it differs from conventional insulation materials used in industrial settings.

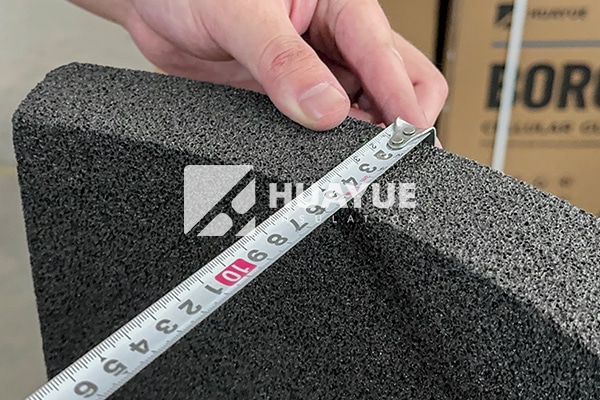

Foam glass pipe insulation is made from glass granules fused with a foaming agent, forming a rigid, closed-cell structure that combines thermal, fire, and moisture resistance in a single product.

Foam glass is not just glass. It is manufactured by mixing recycled glass with a foaming agent, heating it to a high temperature, and then cooling it to form a strong, lightweight block. This process creates millions of tiny, sealed air spaces in the glass, which give it its superb insulating qualities. The result is a material that looks like a rigid, tough sponge and is easy to shape into pipe coverings or tank sections. What matters for plant engineers is the fact that foam glass does not absorb moisture, will not rot or support mold growth, and does not break down under harsh chemicals. It has a high compressive strength too, so it holds up under heavy equipment and outer jacketing. These features let me use foam glass on both hot and cold pipes and tanks, knowing that I am providing reliable, safe insulation for years.

What is the life expectancy of FOAM GLASS?

Insulation materials used on industrial tanks are often replaced every few years due to breakdown or water infiltration.

FOAM GLASS insulation has a service life of 30 to 50 years, remaining thermally efficient, fire resistant, and structurally stable—outlasting nearly all other industrial insulation options.

When planning a new plant upgrade, every engineer considers long-term reliability. Foam glass lasts decades, with a life expectancy from thirty to fifty years depending on installation and use conditions. Unlike fibrous or plastic foam insulations, foam glass does not degrade when exposed to chemicals, high temperatures, or freezing. It resists attack from insects, rodents, and mold because it is inorganic. Over tens of thousands of operating hours, foam glass insulation does not shrink or crack. Corrosion under insulation is minimized because it blocks water entry and provides an inert layer between metal tanks and pipe jackets. I have visited facilities where foam glass insulation installed in the nineties is still performing like new. In the end, FOAM GLASS brings peace of mind and savings over the long haul because it requires little maintenance and never needs frequent replacement.

Conclusion

Foam glass pipe insulation offers reliable safety, long-lasting efficiency, and unmatched corrosion protection for industrial tanks and piping over decades of operation.