If you are planning a tank upgrade or new project, finding the right insulation is a challenge. Foam glass may be the answer, but what about the specs?

Foam glass insulation offers high thermal performance, non-absorption, fire resistance, and long-term stability. It does not absorb moisture, resists chemicals, and can withstand tough environments, making it ideal for industrial tanks and pipes.

When it is time to choose an industrial insulation material, tank engineers must evaluate technical specs and performance. Not all insulation behaves the same, especially in demanding applications. Foam glass offers unique properties that solve many problems in tank systems. In my own work, specs drive every decision.

What is the R-value of foam glass insulation?

Tank insulation needs to perform—R-value tells us how well it resists heat flow. Does foam glass deliver real savings over time?

Foam glass insulation typically offers an R-value of 2.7 to 3.3 per inch. This means it provides reliable thermal resistance for tanks and pipes, helping keep process temperatures stable and energy costs down.

Let’s break down why the R-value matters. R-value measures an insulation’s ability to keep out heat. A higher R-value means better efficiency. With foam glass, typical boards come in thicknesses of 30-150mm. Pipes range from 25-80mm thick with inner diameters from 18mm and length 600mm. Foam glass boards are used mostly for tank and vessel exteriors. Foam glass pipes go on process pipework and tanks.

Foam glass boards and pipes hold their R-value over time. Other insulations can lose efficiency when wet, but foam glass does not absorb moisture. Engineers like Hans Müller count on these specs for long-term performance. This reliability translates into fewer maintenance headaches and better system safety.

What are the key properties of foam glass insulation?

When managing large chemical tanks, safety and durability matter most. What properties help foam glass stand out in tough industrial environments?

Foam glass insulation is non-absorbent, fireproof, load-bearing, and chemically inert. These properties prevent corrosion under insulation (CUI), resist fire risks, and help systems last longer without frequent repairs.

I want to go deeper into these properties.

Non-absorbency is key because foam glass cells are closed, blocking water and vapor. This prevents CUI, a main enemy of industrial tanks. Many other insulations absorb water over time, allowing rust to form on the steel beneath, but foam glass blocks this process.

Fire resistance matters because foam glass insulation is non-combustible. It withstands extreme temperatures without burning or releasing toxic fumes. Fire safety regulations for chemical facilities grow stricter each year. Using foam glass means your tank systems comply now and in the future.

Load-bearing performance is important because tanks and pipework see heavy weight and vibration. Boards and pipe sections do not crush or deform easily. Consistent performance means fewer repairs and less downtime.

Chemical inertness keeps foam glass stable, even when used near acids, alkalis, solvents, and other tough chemicals. In industries like chemicals, oil, and gas, insulation needs to resist reaction with process fluids and vapors. Foam glass stays unchanged.

These features make foam glass fit for demanding industrial environments. It prevents long-term moisture problems, resists fire, carries weight, and stays stable no matter the chemicals used inside a tank or pipe.

What installation and packaging considerations are important for foam glass insulation?

Even the best insulation struggles without proper installation and handling. What should engineers know to avoid mistakes and ensure durability?

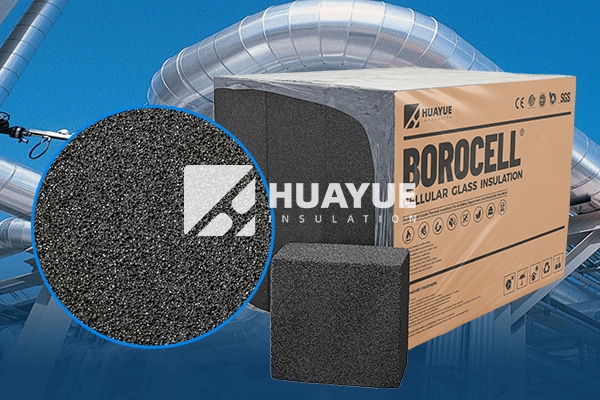

Foam glass insulation boards use carton or hot shrink bag packing and sometimes pallets wrapped with film. During shipment, cartons must stay tightly sealed and stacks upright to prevent damage. Storage should be dry, ventilated, weatherproof, and limited to six layers max. Pipes also need careful handling, and both standard and customized shapes are available, single or multi-layer.

Proper packaging is not just for transport. Foam glass’s structure resists breakage, but poor stacking or exposure to moisture can weaken edges and compromise installation. In my projects, we insist on careful logistics to preserve both board and pipe integrity. Custom shapes and configurations offer flexibility for complex tanks. Single or multi-layer options mean coverage matches the engineer’s needs.

For the brand, HUAYUE INSULATION or authorized OEM branding is available. Engineers like Hans Müller sometimes want their own company’s logo for facility standards. Customized packaging or special reinforcement is offered on request. Small details such as stacking method and warehouse conditions matter, as insulation must deliver reliable results for years.

What are the typical applications of foam glass insulation in industrial settings?

Not every insulation fits every tank or pipe. Which applications make the most of foam glass’s features in industry?

Foam glass insulation suits cryogenic tanks, chemical tanks, and process pipework, where moisture resistance, fire safety, and durability are vital. Common uses include exterior tank insulation, internal pipework, elbows, and custom tank shapes for long-term energy saving.

Foam glass boards are used on tank walls, roofs, and floors. Pipe sections wrap around process lines, bends, and connectors. Custom cuts simplify fitting irregular-shaped vessels. Foam glass excels in cryogenics, where keeping cold is essential, and it also defends hot process pipes against heat loss and CUI. Chemical plants, refineries, and food production facilities all rely on foam glass for safe, efficient operations.

In my experience, companies get better long-term performance with fewer replacements or breakdowns. Hans looks for these results when making system upgrades to meet evolving safety codes and cut costs.

Conclusion

Foam glass insulation delivers reliable specs, top thermal efficiency, and proven durability for industrial tanks and pipes.