WholesaleBorosilicate Foam Cellular Glass Block

Looking for a reliable, quick-turn, long-term manufacturer of

Borosilicate Cellular Glass Block?

With advanced production lines and technology, the unmatched capacity of over 200,000 M2 of our factories ensures your Borosilicate Cellular Glass Blocks are shipped on-time, every single time. At HUAYUE, our ISO9001-certified manufacturing facilities and well-trained workers are our best wealth and guarantee for high quality final borosilicate glass blocks with capabilities like tighter tolerances, qualified specifications, and perfect packaging.

We’re your single manufacturer of borosilicate cellular glass block in bulk wholesale with manufacturing tailored to your project needs.

BoroCell® CL200 Borosilicate Cellular Glass Block

Outstanding corrosion resistance and thermal insulation in wet gas environments

- Block Dimensions: 152mm x 229mm x 38mm or 51mm

- Density: 185 – 220 kg/m3

- Compressive Strength: ≥1100 kPa

- Thermal Conductivity: ≤ 0.087 W/m·K

To Customize Your Borosilicate Cellular Glass Block

The Ultimate Guide Of Borosilicate Cellular Glass Block

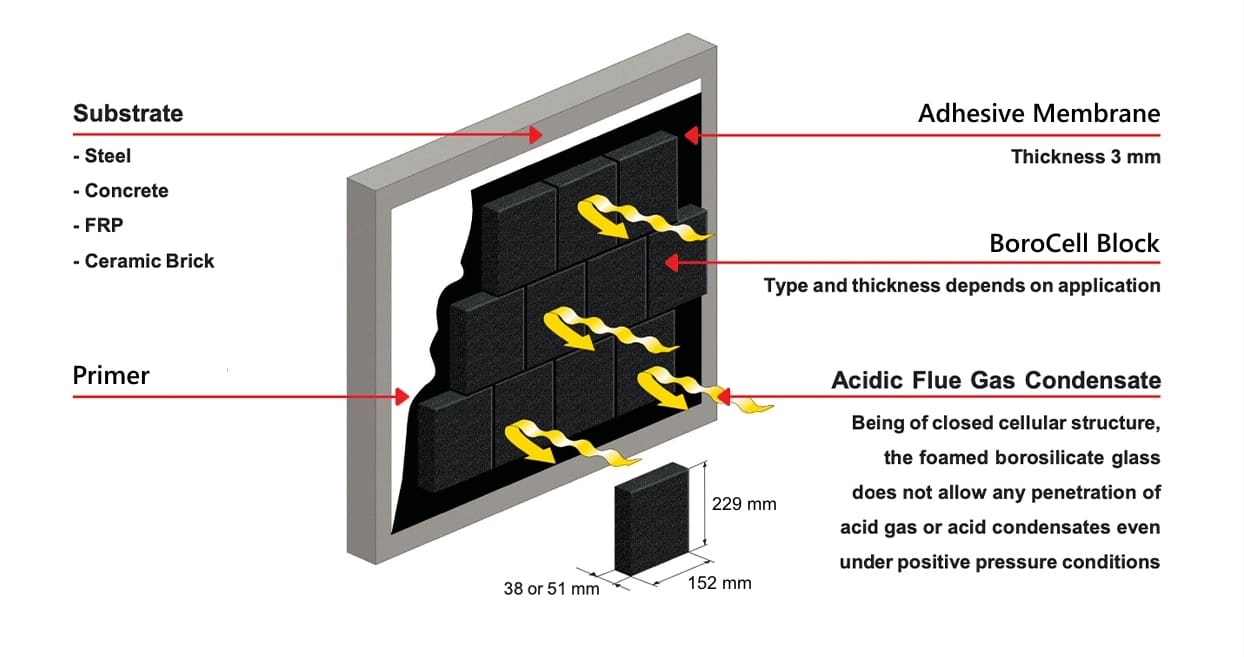

HUAYUE BOROCELL® BLOCK LINING SYSTEM

How our borosilicate cellular glass block lining protects your chimney?

BoroCell® borosilicate cellular glass block can be operated at temperatures up to 516°C, and this borosilicate foamed glass block lining system can be operated at temperature 200°C. Because the cellular glass block is an excellent insulator, the ductwork and liner are not required to be insulated after the foamed glass block is installed.

Because of its high insulative properties and low thermal mass, BoroCell® borosilicate cellular glass block will minimize the quantity of thermal condensation within the liner during unit startup. The block also provides some level of protection to the base-liner material in the event of a stack fire. In such a situation, the lining system will most likely need to be replaced, but the structural portion of the liner may be undamaged.

Cost efficient construction and maintenance

BoroCell® borosilicate cellular glass block can be attached directly to the inside surface of a concrete shell. This technique has been used to reduce the cost of stacks and also as a method for reusing older stacks whose liners are not favorable for wet operation.

Excellent properties as most versatile lining materials

First of all, borosilicate cellular glass is a material with a very low coefficient of thermal expansion, and the glass volume will not produce a sharp change in case of temperature shock, and the cellular glass blocks made of borosilicate glass can withstand the temperature change of 100°C in the chimney remaining uncracking. Secondly, the borosilicate glass foam brick is kind of thermal insulation material, so there is no need to place new insulation layer after the original one is dismantled. No matter in dry flue gas conditions or in wet flue gas conditions, the thermal insulation property of the borosilicate cellular glass blocks themselves will ensure the temperature change of chimney concrete wall within the acceptable temperature range(<199°C). Finally, the borosilicate cellular glass block offers excellent corrosion resistance and can remain undamaged for a long time. It can truly protect the chimney by isolating the corrosion and heat source from the concrete wall.

The borosilicate cellular glass block should have acid resistance, lightweight, high thermal shock strength, small linear thermal expansion coefficient, small thermal conductivity, no water absorption, no combustion, no deformation, etc., with bondable and easy cutting properties. BoroCell® Borosilicate foam glass block shall meet all the requirements mentioned above.

Huayue Borocell® Block Lining System

The most versatile industrial borosilicate glass block industrial chimney lining for fossil fired power stations.

Impermeable to acid gas and acid condensates

Due to their closed-cell structure, the borosilicate glass blocks are completely impermeable to acid gas and acid condensates even under positive pressure conditions.

The Adhesive is a 2-component urethane asphalt mastic that bonds the borosilicate glass blocks to the substrate. The adhesive remains flexible in the long term, allowing the BoroCell® Block Lining System to last, potentially for decades.

The BoroCell® Block Lining System is uncomplicated to install by local semi-skilled workers, under expert supervision. The lining can be installed onto a range of substrates such as steel (even when already corroded or coated), concrete and brick (even if in poor condition).

Compliance with emission standards

Power plants are required to comply with strict emission standards and other environmental laws and regulations. BoroCell® chimney lining protects the interior of a power plant chimney from damage caused by flue gases and keeps chimneys in good condition. Our lining block has a proven track record of successful operation in FGD wet stack conditions. As such, it reduces the risk of costly unscheduled maintenance and downtime.

Additionally, a high-quality chimney lining helps limiting pollution by reducing the emission of SO2, NOx and particles into the environment.

Long-term warranty services for chimney linings

Huayue BoroCell® is your industrial chimney lining expert. We have supplied high-quality borosilicate linings glass blocks all over the world.

Our industrial BoroCell® borosilicate foam glass blocks for chimney linings come with a full 10-year warranty from the date that the power plant commences operation, to assure optimum performance of the lining system during its entire life span.

BoroCell® borosilicate foam glass blocks have stable performance and meet the 30-year maintenance-free use requirements conditions specified by our EPC clients and power plant end users.

An increasing number of plants are utilizing borosilicate-block lining systems. All the specific parameters of BoroCell® borosilicate foam glass blocks used as chimney lining meet the requirements of the properties of the products asked by the power plant end user.

Would you like to know more?

Do not hesitate to contact us. We are happy to discuss and the solutions we can offer to the challenges you are facing.

How A Borocell® Lining Protects Your Stack

Uncomplicated installation method and suitable for a wide range of substrates

Highly suitable for new and existing chimneys and ducts

CHEMICAL RESISTANCE

For low temperature wet flue gas to high temperature untreated gas, even with a high SO₂ content

TEMPERATURE RESISTANCE

Up to 200 °C or even higher for short periods

THERMAL SHOCK RESISTANCE

Most thermal shocks have no effect on BoroCel® borosilicate glass block linings

LOW WEIGHT

Does not require anchors, earthquake resistant

LONG SERVICE LIFE

Virtually no maintenance

Material Selection: Options for wet flue gas chimney lining

Wet limestone flue gas desulphurisation (FGD) systems have been selected for their efficiency and low running cost by almost all power companies all over the world for removing sulphur dioxide from flue gas and complying with the emission control of the policy of Environment and Climate Change.

The clean flue gas streaming out of an FGD system is 100 per cent water saturated and condenses in the outlet duct connecting to the chimney and in the chimney itself. The condensate is a diluted sulphuric acid (1 per cent), which is highly corrosive for the outlet duct and the chimney.

The wet environment created by the FGD process has created new demands on chimney liners and ductwork:

- The surface of the liner must be resistant against condensate

- The liner will mainly be operated in overpressure

- Adapted flue gas speed (tearing off condensate film)

- Adapted smooth surface (no edges)

- Liquid collection system for condensate

- Mounting of drip-catchers

- Muzzle formation in consideration of the down-wash effects

In the recent past, when there were no FGD systems installed, the flue gas would be dry and so there was no chance of corrosion of the steel liners. In many countries, for wet flue gas FGD projects, most contractors and major power companies prefer to use borosilicate glass block linings inside steel flues and some contractors companies also give options for metallic solutions such as titanium sheet and high nickel alloy “C 276”.

Several types of lining material and coating system are available and have been used successfully in worldwide in outlet ducts and chimneys downstream of wet FGD systems. The advantages and disadvantages of each system must be considered prior to the selection of the lining material or coating. The following table describes the most common materials that are currently considered appropriate for wet stack applications. These materials have previously been utilized with some degree of success. Other materials and suppliers may be available and acceptable, and they should be evaluated on a case-by-case basis. Operation condition, design condition, and economics etc., all play important roles in this decision. The analysis of key factors including advantages and disadvantages of several different lining and coating system options, are presented in following table that can help the purchaser to choose between them.

| Liner Material or Coating | Advantages | Disadvantages |

| Fiberglass Reinforced Plastic | Good corrosion resistance; Easy to add liquid collection devices. | Maximum 300F(149“C) (approx.) gas-temperature exposure; Quality control during fabrication; Compressive strength limitations, usually requires two support levels and expansion joint; Only suitable for chimney with inner cylinder. |

| Borosilicate Cellular Glass Block | Good corrosion resistance; Good insulator (ductwork and liner should not be insulated); Ability to retrofit to existing steel liner systems; Good surface for liquid flow; Clearly more economical; Low life cycle cost, successful operating experience with maintenance-free exceeding 30 years in many power stations; Can handle higher flue gas velocities than those lined with titanium or high nickel alloy; Widely suitable for various kinds of chimney. | Cannot tolerate abrasion; Care in installing. |

| Acid-Resistant Brick | Good corrosion resistance; Cost-effective; Liquid adheres to the porous surface. | Surface discontinuities re-entrain liquid; Not recommended in high seismic areas; Maintenance of liner accessories; Annulus pressurization; Only suitable for chimney with inner cylinder. |

| Protective Coating on Carbon Steel | Fair corrosion resistance; Ability to retrofit to existing steel liner systems. | Surface preparation prior to placement; Frequency of repair and maintenance; Limited acceptable selections, only suitable for Carbon Steel. |

| Alloy C276 | Excellent corrosion resistance | Welding quality control; High material costs, much higher than other liner materials; Welding seams; lron Contamination; Acid cleaning; Condensation; Only suitable for chimney with inner cylinder. |

| Titanium Sheet | Excellent long-term corrosion resistance | Exposure risk of the mild steel flue to wet flue gases through the welding porosities caused during steel flue construction |

The main factor to be considered in material selection for lining of FGD wet stacks is its chemical resistance to high humidity and the acidic operating environment. Below are some of the major testing parameters for checking if the lining material is suitable to achieve the desired performance in such an environment for a service life of up to 30 years.

- Chemical resistance to acid

- Wet stack surface properties

- Thermal shock resistance

- Health and safety properties during installation

- Fire and earthquake resistance

Among all three main options (borosilicate glass block, titanium sheet and high nickel alloy C276) for chimney linings, almost all major power companies have allowed construction contractors to choose and specify borosilicate cellular glass block due to its evident advantages over other materials, especially its ultra long life service cycle, economical cost, excellent insulation performance itself, widely suitable for various kinds of chimney, etc. Globally, it is quite common for power plants to use borosilicate cellular glass block, which has been proven best chimney lining material in actual use.

Where To Use Our Borocell® Borosilicate Cellular Glass Block Linings

BoroCell® Closed-cell Borosilicate cellular glass block can be applied equally well in new and existing power plant chimneys as well as flue gas ducts onto a variety of substrates such as steel (even when already corroded), concrete, ceramic brickwork, FRP and organic coatings. Structural modifications are usually not required.

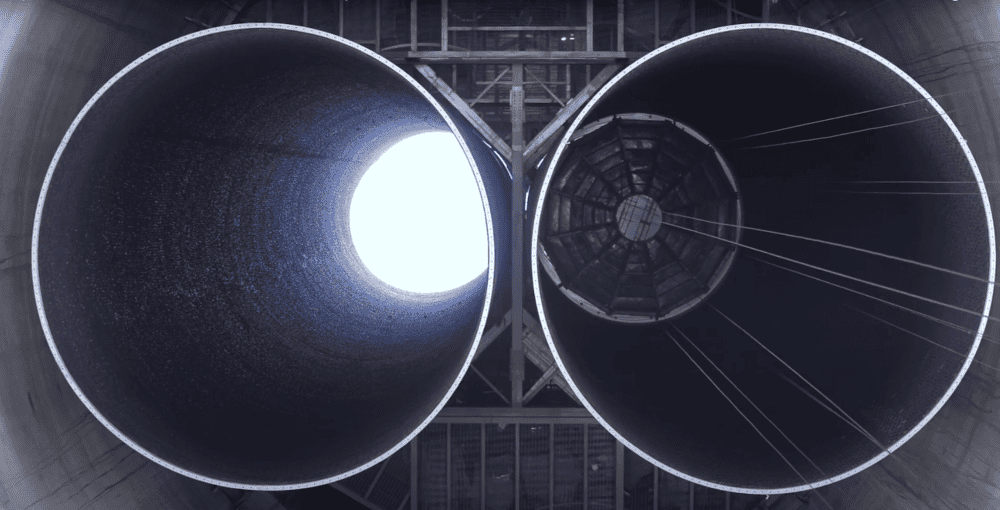

New Steel Chimneys / Flues

BoroCell® Borosilicate linings are frequently used in new steel chimney flues and free-standing steel chimneys.

- Compatible with a variety of construction methods

- Lightweight

- Compatible with a variety of construction methods

- Resistant to a wide range of operating conditions, including FGD, both reheated and "wet stack"

- Virtually no maintenance

- Service life exceeding 30 years

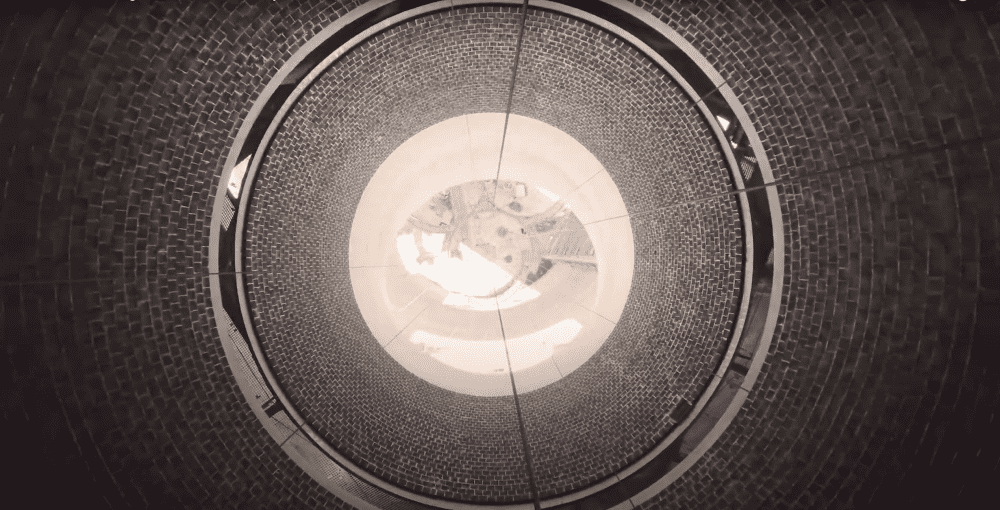

New Industrial Chimney Design

New Chimney Design: BoroCell® borosilicate glass block linings directly applied to the inside surface of a concrete chimney shell.

- NO internal flues / liners needed

- 20% less expensive to build

- Slim, lightweight, built to last, also for seismic regions

- Resistant to a wide range of operating conditions

- Low maintenance, minimal risk of component failure

Existing Chimneys

BoroCell® linings can be applied in existing chimneys to almost any substrate.

- No need to demolish and rebuild

- Applied to almost any substrate, including steel, concrete, FRP and brick (even if in poor condition)

- Can replace internal flue altogether

- Structural modifications not usually required

- Can be installed quickly, also in stages avoiding long outages

New And Existing Ducts

BoroCell® linings will protect new and existing ducts. In existing ducts, BoroCell® linings offer the advantage of high tolerance of surface imperfections such as pitting corrosion and weld roughness.

- Suitable for newly built and existing ducts

- More economical than replacing sections of existing ductwork

- Versatile – for inlet, outlet and bypass ducts

- No expensive external insulation required

- Lightweight, durable and reliable

- Suitable for a wide range of fuels (coal, oil, petcoke, lignite, biofuels) and operating conditions

- Long service life of more than 30 years and require very little maintenance even under highly acidic conditions

Other Typical Applications

Besides being used as a lining in power station chimneys, stacks, flues and ducts, as a chemical resistant, lightweight materials, BoroCell® block can also be used as insulating layer in chemical processing vessels and sulfur pits, etc. Typical application areas also include:

- Chemical Industry

- Petrochemical Industry

- Waste Water Treatment Plants

- Flue Gas Environments

- Pulp and Paper Plant

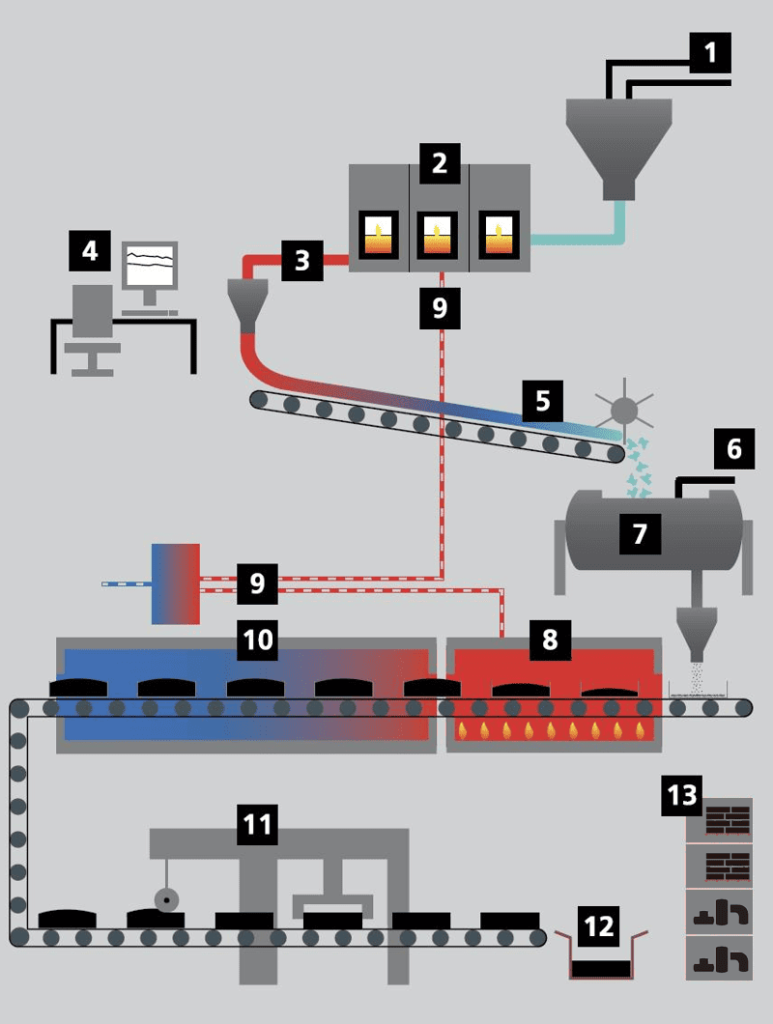

Manufacturing Process

HUAYUE BoroCell® Borosilicate Cellular Glass Block manufacturing process largely consists of glass production process and cellular glass manufacturing process. For raw material of glass, cellular glass can be manufactured using recycled waste glass, but the property of final products depends on the quality of raw materials. Thus, although using waste glass can save cost to produce products, it is not practical when the aspect of quality of products should be considered.

HUAYUE BoroCell® Borosilicate Cellular Glass Block is manufactured primarily from melting new raw glass and abundant natural raw materials. In our factories the principal raw material used to create BoroCell® Borosilicate Glass Block is melting new glass with precisely defined properties, the key to making excellent properties. The mix of raw materials and adjustments during the manufacturing process determine the unique combination of HUAYUE BoroCell® Block properties.

Mixing and batching of the raw materials: Melting new raw glass, recycled glass, feldspar, sodium carbonate, iron oxide, sand, sodium sulphate, sodium nitrate.

The melting furnace has a constant temperature of 1250°C.

Molten glass is drawn out of the furnace.

Control room for monitoring the production.

The glass is drawn off and falls onto the conveyor belt where it cools down before entering into the ball mill.

Addition of “carbon black”.

Energy recovery of heat.

The HUAYUE® blocks pass through an annealing oven to allow carefully controlled cooling of the block without thermal stress.

The blocks are cut to size and sorted by batch. Production Waste returns back into the process.

HUAYUE® slabs are then packaged, labelled and palletized.

Packaging & Shipping

Packaging

HUAYUE provides reliable packaging solutions for BoroCell® Borosilicate Cellular Glass Block.

- There is a safe anti-abrasion solution inside the box.

- Boxes are strapped with transport plastic ribbons or sealed by adhesive tape.

- The pallet size is dynamically customized to fit the box dimensions. The corners of boxes are protected with cardboard. Pallets with boxes are wrapped in protective transparent film and strapped with transport plastic ribbons.

- The customized OEM on packaging is available. The wholesaler’s designs such as logo patterns are welcome to be customized based on their requirements.

Shipping

On-time delivery

Throughout the entire process of our supply chain management, consistent on-time delivery is vital and very important for the success of our business. Our warehouse department makes sure that your products are stocked properly before being delivered by transportation department. Close collaboration between our multiple departments, including production, makes us experts in what is of the utmost importance to you—on-time delivery.

Shipping service you know and trust

Huge care and expertise are employed in packing and shipping foam glass, but it’s still vulnerable during transport. We track the whole process of loading containers or vehicle and monitor the ongoing performance of the forwarders to ensure high standards of care and punctuality are maintained. “Loading Process Tracking Documents” sending to you after loading enables you to know the instant and real process.

How Can We Handle Your Order And Duration Estimation

At HUAYUE, our top priority is ensuring a simple and efficient experience for our customers, from the initial consultation to the production and ongoing delivery of your Borosilicate Cellular Glass Block. We understand the importance of a well-organized process and have refined our approach to provide you with the best possible service. Here’s how we handle your order:

Step 1: Make A Query (Within 1 day)

Our borosilicate cellular glass block products come with detailed descriptions of their technical specifications and any other information you need to make an informed buying decision. You can make as many queries for as many borosilicate cellular glass block as you like. We’ll respond to all of them.

Not sure what you’re looking for or have any other questions? Simply fill out our query form here. Someone from our team will reach out to you to discuss your concerns.

Step 2: Talk To Us (1-3 days)

Once you’ve submitted a query, someone from our team will contact you within 12 hours. Talk to our representative about your borosilicate cellular glass block needs.

To get an instant quotation from our professional team, please specify:

– demand quantity

– the demanding size (length/width/thickness);

– the specifications you care about;

– specific application;

– project name, located country, project owner and EPC contractor;

– important requirements from the contractor/lead engineer/owner of the project (if any).

Already sure about the borosilicate cellular glass block product you want? Just talk to our representative to confirm all the above accurate information. Our representatives will then give you a price quote based on your choice of borosilicate cellular glass block.

Step 3: Verify Sample (3-7 days or not)

Before confirming your order, due to your responsibility to the owner or end user or other reasons, you may still be uneasy about the quality of our products. A free sample is available for verification to ship to your address directly, fast express delivery service enables you to get the samples ASAP. Of course, if you recognize our strength, we can also omit this step.

Step 4: Confirm Your Order (Within 1 day)

After deciding all above information, confirm your order at HUAYUE. We’ll send you a confirmation email with all the details of your order including quantity and price, order processing time, and payment information.

Step 5: Pay The Advance Bill And Bulk Manufacturing (1-30 days)

Once your order is confirmed and advance payment arranged, we’ll take care of the rest. Our team of experts will get to producing and packaging your bulk borosilicate glass block.

Step 6: Sit Back, Relax And Wait For Your Order To Be Delivered (7-40 days)

After finishing manufacturing and packaging and arranging balance payment, we will ship your order and handle the export customs clearance process, our trusted carriers will get it to you in no time. Once the products arrive at your destination port, you will receive an alert. You can plan how to collect your shipped goods with all the documents provided by us.

Own Factory Capabilities

Our Production Line

We guarantee that all our products have passed the quality control and stringent regulations imposed not only by our company but also by international organizations. Our certifications assure that our product line is top grade by industry standards.

In addition, HUAYUE has established a multi-functional physical chemistry laboratory for continuous quality supervision, equipped with reliable testing equipment and instruments adopted to test and control production, to guarantee product quality.

As currently one of the best borosilicate cellular glass block manufacturers in the world, with 6 cellular glass production lines, products cover the ASTM standard to the European standard full series, to provide customers with stable high-quality products in fast delivery.

Enterprise Certificate

HUAYUE has also passed the highest quality management standards imposed by the International Organization for Standardization (ISO). We have passed ISO 9001 for the manufacture and design of our foam cellular glass series.

We have also received CE, SGS certificates for passing the Standard Testing. As a borosilicate cellular glass block manufacturer, complying with certain industry standards enables us to be competitive in the highest quality products anyway. BoroCell® borosilicate cellular glass block can be certified to conform to the requirements of ASTM STANDARD of cellular glass block and all the technical requirements of projects specified by the owner and contractor.

Request for certification shall be included with valid order for HUAYUE BoroCell® borosilicate cellular glass block.

Things To Consider When Buying Foam Glass in Bulk

There are many things to consider when you’re buying borosilicate cellular glass block in bulk online. You need to make sure you choose the capable manufacturer and borosilicate cellular glass block that has the right technical specs and size you need. Here are some other points to consider:

Certifications and Test Report

Make sure you double-check the exact specifications of foam cellular glass properties. Different suppliers (maybe not manufacturers) provide different properties of borosilicate cellular glass block. It may happen that some suppliers provide you with borosilicate glass block that actually does not meet your requirements, and you don’t realize it. So it’s important to ask if they have any industry-relevant certifications and test reports for borosilicate cellular glass block. However, some weak suppliers do not have these at all.

Product Quality

Checking the quality of borosilicate cellular glass block is really important before you buy any, especially in bulk. Check the borosilicate cellular glass block manufacturer’s production process to see what kind of raw materials and processes they use. Also, inquire about their quality testing procedures.

Turnaround Time

Ask the borosilicate cellular glass block manufacturer or supplier to relay the exact time or timeframe it will take for your borosilicate cellular glass block to be delivered. Custom or bulk orders usually have a longer turnaround time but not an unrealistic time.

Manufacturer Or Trader?

Should you buy borosilicate cellular glass block in bulk from borosilicate cellular glass block traders? Or should you choose borosilicate cellular glass block manufacturers? Look at the comparison chart below to see why you should buy borosilicate cellular glass block in bulk from a manufacturer.

| Borosilicate Cellular Glass Block Manufacturer | Borosilicate Cellular Glass Block Trader |

| QUALITY | |

You can easily gauge the quality of borosilicate cellular glass block manufacturers by looking at their borosilicate cellular glass block production process and getting information regarding the QA tests they perform. Borosilicate cellular glass block manufacturers have better quality products anyway, since they have to comply with certain industry standards. | Traders may sell borosilicate cellular glass block products they got from borosilicate cellular glass block manufacturers or other suppliers. So it is hard to check the quality of the products. Traders also don’t usually have information regarding the production of borosilicate cellular glass block products so you can’t verify if the products they sell meet the industry standards. |

| CUSTOMIZATION | |

| Borosilicate cellular glass block manufacturers have the ability to create customized borosilicate cellular glass block products as per your requirements with high flexibility. OEM and ODM can be fully met. | Traders cannot custom-make any borosilicate cellular glass block products for you. Sometimes they can only accept very limited customization. You only have the option of choosing from whatever products they sell. |

| RELIABILITY | |

| Borosilicate cellular glass block manufacturers take full responsibility for the products they sell. They can provide warranties for a longer time. | Traders are dependent on the Borosilicate cellular glass block manufacturer warranties. They cannot handle troubleshooting requests or help with other technical issues. |

Choosing a borosilicate cellular glass block manufacturer for your wholesale borosilicate cellular glass block orders is preferable because it gives you the chance to discuss the nuances of your project with a professional.

Why Choose Us for Wholesale Borosilicate Cellular Glass Block

As one of the leading borosilicate cellular glass block making companies in China, HUAYUE can handle any need for borosilicate cellular glass block from our clients. Not only do we manufacture borosilicate cellular glass block products but we can also customize, store, and ship them for you. So, if you are searching for a reliable Chinese borosilicate cellular glass block manufacturer, our company would be your best pick because we have the following advantages:

High Annual Output

HUAYUE can manufacture a large quantity of borosilicate cellular glass block of over 200,000 square meters annually. We have advanced foam glass manufacturing facility and efficient workers that allow us to produce borosilicate cellular glass block that meet the quantity demand globally.

Wholesale Borosilicate Cellular Glass Block Price

Our high-quality borosilicate cellular glass block is available at wholesale rates which saves you money and reduces your costs of production.

Fast Production Turn-around

We manufacture your borosilicate cellular glass block products fast to ensure that the construction work and distribution schedules of your business are not delayed or disrupted. Our infinite manufacturing capacity means stable supply and on-time delivery for you.

Free Borosilicate Cellular Glass Block Sample

HUAYUE offers you a free borosilicate cellular glass block sample for testing and to confirm that we meet your requirements.

Low Minimum Order Quantity

All our clients are important to us and thus we set our MOQ lower to accommodate large and small orders.

High Borosilicate Cellular Glass Block Quality

We are meticulous with our quality checks and manufacturing standards. Our goal is to offer you the best borosilicate cellular glass block.

Worry-free Aftersale Services

The HUAYUE team is always on hand to guide you through aftersale procedures such as warehousing, shipment, and just-in-time delivery.

Wholesale Borosilicate Cellular Glass Block FAQs

Sure, free samples are available. Just tell us your freight collect account like FedEx DHL TNT, if you don’t have an account, it needs to charge Express fee properly.

Proforma invoice will be sent first after confirmation of the order, enclosed our bank information. Then payment could be arranged by your side.

We provide SDS, TDS, Commerical Invoice, Packing List, Bill of Loading, Certificate of Original, Insurance, etc. If your markets have any special requirements, let us know.

- Samples – Making samples for you to check.

- Confirm Order – Signing sales contract or issuing PO after samples are confirmed.

- Deposit – 30% deposit before mass production.

- Production arranged – We will process the production.

- Remaining payment – After inspection, balance before shipment.

- Shipping – We will ship the goods to the destination port.

- Documents – Confirm bill of loading/commercial invoice/packing list/certificate of origin.

- After sales service – Solve your problems after you receive the goods.

Yes, wholesaler’s designs such as size, pattern, packaging, etc are welcome to be customized based on their requirements.

For large orders, T/T payment is more universal, but please note that for new customers, we only accept the 30% T/T of the deposit payment, or if you have been with us for years and run into cash flow pressure, we do offer L/C, OA credit. If you have another question, please feel free to contact us.

Of course, we welcome you and the third-party inspection you entrust to come to our factory anytime. Now we also support using ZOOM or other tools for online factory inspection.

It hasn't happened since HUAYUE was established. We are confident that HUAYUE has 25 years of experience in the industry, we have far more experience than others.

Stocked model 100 square meters above; Customized size, please feel free to contact us.

- For samples, 3-7 working days door to door by air.

- For stocks, within 7 days can be shipped to the loading port.

- For mass production, it depends on the quantity of orders and whether you want to do customization with your borosilicate glass block or not, and also depends on the speed of customs clearance and logistics, but we can guarantee to ship goods in the shortest time, and we have customers in Vietnam who received the goods in less than 1 weeks.

The material of our borosilicate glass block products is 100% pure raw glass we produce in our melting furnace, we never use recycled low-grade glass, and the glass contains many impurities, which will greatly affect the quality of borosilicate glass block. This is unmatched by other factories.

In a word, China has a much better industry chain. There may be wholesalers of borosilicate glass block in USA, but HUAYUE can guarantee that our prices can be on par with theirs and our service far exceeds your expectations.

- For small trial orders, by air or by express: FedEx, DHL, UPS, TNT, etc.

- For large orders, we arrange shipment by sea or by air according to your requirements.

Foam Cellular Glass Wholesale Can Be Easy & Safe.

Start earning substantial profits in your country today!

Foam Cellular Glass wholesale can be easy. HUAYUE has helped customers in more than 30 countries to be successful and earn good profits. We also welcome you to become a distributor in your country.

After signing the agreement, your orders will be processed and shipped first. Click the buttons below, and let’s grow your brand together.

Don’t hesitate to contact us. Send us a message if you have any questions or request a quote or free samples. Our experts will give you a reply within 12 hours and help you solve various problems.

Need an expert? you are more than welcomed to leave your contact info and we will be in touch shortly.